Home » Industrial

Leveraging the unique proprietary compatibilizer technology of its sister company, Nordic Grafting Company A/S, CCS incorporates Acti-Tech™ compatibilizers into a new series of thermoplastic vulcanizates (TPVs). Special grades can be tailored for improved adhesion to various surfaces, enabling efficient design and manufacture of lighter, multi-material systems. This is an obvious example of creative, more sustainable solutions, increasingly required by industrial markets. CCS also privileges more environmentally friendly raw material options in order to ensure compliance to more stringent norms, applicable today in wire and cable or building and construction end-uses.

Some of most demanding industrial applications can be found in the cable industry. System suppliers and their cable manufacturers are constantly looking for polymer materials for jacketing and/or insulation layers that balance flexibility and sustained mechanical properties with, increasingly, flame-retardancy without the presence of halogen-based components. CCS commercializes two lines of products for these end-uses. First, two proven, cost competitive Opti-Pren™ HFFR (halogen-free flame retardant) thermoplastic elastomers grades have been part of the CCS portfolio since the company was created. In addition, CCS is developing a superior range of higher performance zero halogen flame retardant thermoplastic vulcanizates (TPVs), the Opti-Pren™ TPV 6400 ZHFR series, with the intent to respond to more demanding electrical applications, whether molded or extruded.

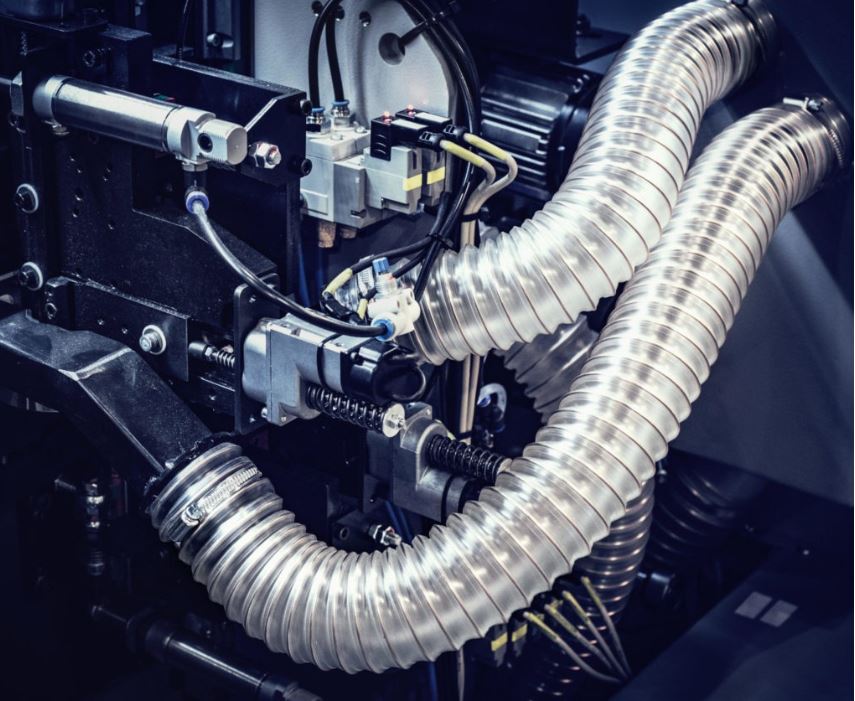

Opti-Pren™ TPV 6200 series, characterized by its high mechanical properties, yields high level of (chemical) adhesion to polar substrates, like reinforced yarns/ nonwovens made from polyester, aramid or carbon fibers. Low friction and superior UV resistance can be designed in new formulations upon demand. Targeted applications for this offering include reinforced hoses and tubes.

In industrial applications, parts are often expected to retain their full functionality and aspect for an extended period of time. Durability has therefore now become of key selection criteria for raw materials, whether for extruded or injection molded end uses. CCS has developed a new series of high tensile TPVs with superior abrasion in this class of thermoplastic elastomers. Opti-Pren™ TPV 6800 series can be available in a variety of hardnesses, from a soft 50 Shore A version to a medium durometer grade of 80 Shore A.

Customized Compound Solutions A/S

Søholm Park 1

2900 Hellerup

Denmark

Direct number:

+45 35 43 88 43

Customer service:

ccs-customerservice@bjorn-thorsen.com

VAT no. DK36732776